Technology for large-scale protein manufacture unveiled

Posted: 11 September 2015 | Victoria White

Researchers have developed the user-friendly technology to help scientists understand how proteins work and fix them when they are broken…

Researchers have developed a user-friendly technology to help scientists understand how proteins work and fix them when they are broken.

Such knowledge could pave the way for new drugs for a myriad of diseases, including cancer.

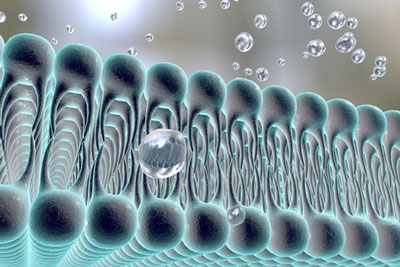

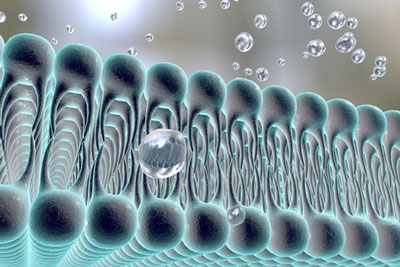

The human body can turn its proteins on and off to alter their function and activity in cells: phosphorylation, the reversible attachment of phosphate groups to proteins. These “decorations” on proteins provide an enormous variety of function and are essential to all forms of life. Little is known, however, about how this dynamic process works in humans.

Using a special strain of E. coli bacteria, the researchers from Northwestern University and Yale University have built a cell-free protein synthesis platform technology that can manufacture large quantities of these human phosphoproteins for scientific study. This will enable scientists to learn more about the function and structure of phosphoproteins and identify which ones are involved in disease.

“This innovation will help advance the understanding of human biochemistry and physiology,” said Michael C. Jewett, a biochemical engineer who led the Northwestern team.

Trouble in the phosphorylation process can be a hallmark of disease, such as cancer, inflammation and Alzheimer’s disease. The human proteome (the entire set of expressed proteins) is estimated to be phosphorylated at more than 100,000 unique sites, making study of phosphorylated proteins and their role in disease a daunting task.

Scientists can now make phosphoproteins at “unprecedented yields”

“Our technology begins to make this a tractable problem,” Jewett said. “We now can make these special proteins at unprecedented yields, with a freedom of design that is not possible in living organisms. The consequence of this innovative strategy is enormous.”

As a synthetic biologist, Jewett uses cell-free systems to create new therapies, chemicals and novel materials to impact public health and the environment.

“This work addresses the broader question of how can we repurpose the protein synthesis machinery of the cell for synthetic biology,” Jewett said. “Here we are finding new ways to leverage this machinery to understand fundamental biological questions, specifically protein phosphorylation.”

Jewett and his colleagues combined state-of-the-art genome engineering tools and engineered biological “parts” into a “plug-and-play” protein expression platform that is cell-free. Cell-free systems activate complex biological systems without using living intact cells. Crude cell lysates, or extracts, are employed instead.

Specifically, the researchers prepared cell lysates of genomically recoded bacteria that incorporate amino acids not found in nature. This allowed them to harness the cell’s engineered machinery and turn it into a factory, capable of on-demand biomanufacturing new classes of proteins.

Technology will enable scientists to decrypt the phosphorylation code

“This manufacturing technology will enable scientists to decrypt the phosphorylation ‘code’ that exists in the human proteome,” said Javin P. Oza, a postdoctoral fellow in Jewett’s lab.

To demonstrate their cell-free platform technology, the researchers produced a human kinase that is involved in tumour cell proliferation and showed that it was functional and active. Kinase is an enzyme (a protein acting as a catalyst) that transfers a phosphate group onto a protein. Through this process, kinases activate the function of proteins within the cell. Kinases are implicated in many diseases and, therefore, of particular interest.

Related organisations

Northwestern University, Yale University