Laser cut microwells could lower the cost of cancer research

Posted: 26 January 2016 | Victoria White | No comments yet

Researchers say the fabrication technique could slash 90% of the cost of mass-producing metastatic microtumours and therapeutic microtissues for screening and research…

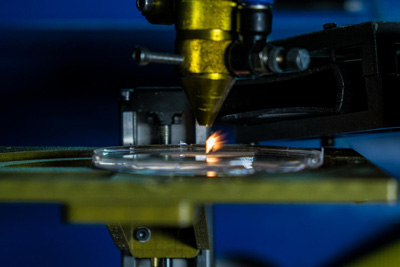

Rice University bioengineers have reprogrammed a commercial laser cutter to etch up to 50,000 tiny “microwells” per hour into sheets of silicone.

The fabrication technique, which was developed with open-source software and hardware, could slash 90% of the cost of mass-producing metastatic microtumours and therapeutic microtissues for screening and research.

“Microwells can be used to grow tiny clusters of cells,” said Rice bioengineering researcher Jordan Miller, the lead researcher on the new study. “These clusters, or multicellular aggregates, contain 50-100 cells and have many potential applications, but they have been difficult to mass-produce. In the field of cancer biology, multicellular aggregates are used to model cancer micrometastases — small microtumours that can occur in high numbers in cancer patients. And in the field of regenerative medicine, they can be used as living building blocks to fabricate tissues and organs from a patient’s own cells.”

To study micrometastases in the lab, researchers grow multicellular aggregates of tumour cells. Traditionally, scientists have formed these by manually placing individual droplets of cells onto a plate using a pipette. But Miller said this method is labour-intensive, highly variable and typically produces small numbers of usable samples, which makes it impractical for studies that may require thousands of aggregates.

Although commercial microwell products are on the market, Miller said they can be expensive, and the wells also come in a limited selection of shapes and sizes, which can make it difficult to produce small aggregates.

50,000 microwells per hour

Miller and graduate student Jacob Albritton found they could produce up to 50,000 microwells per hour by developing hardware and software modifications for a commercial CO2 laser cutter.

“We found we could create a conical well with a millisecond laser pulse in a sheet of poly(dimethylsiloxane), or PDMS,” Albritton said. The material is a silicone-based organic polymer that’s commonly used in industrial fabrication. This polymer is also nontoxic to living cells and is used often in biological experiments.

“When the laser flashes across the surface, it’s like a Gatling gun, and you can see little spouts of flame from each strike,” Albritton said. “Our laser-based fabrication method can achieve something that standard lithography cannot: sharp, conical depressions that help guide the cells into a single aggregate.”

Regarding production costs, Miller said, “Using our technique, it costs around $30 to fabricate 100,000 microwells. This is less than one-tenth the cost of commercial sources.”

Albritton said, “When we seed cells onto microwell sheets, they settle into the bottom of each microwell and form into aggregates overnight.”

He said the team found it could produce wells of different depths and shapes simply by varying the power and duration of the laser pulses, a technique that could produce specialsed microwells that haven’t been available previously.

Related topics

Oncology

Related organisations

Rice University