Building reliable organoid models for human-relevant drug discovery

Posted: 17 October 2025 | Sam Wightwick (Drug Target Review) | No comments yet

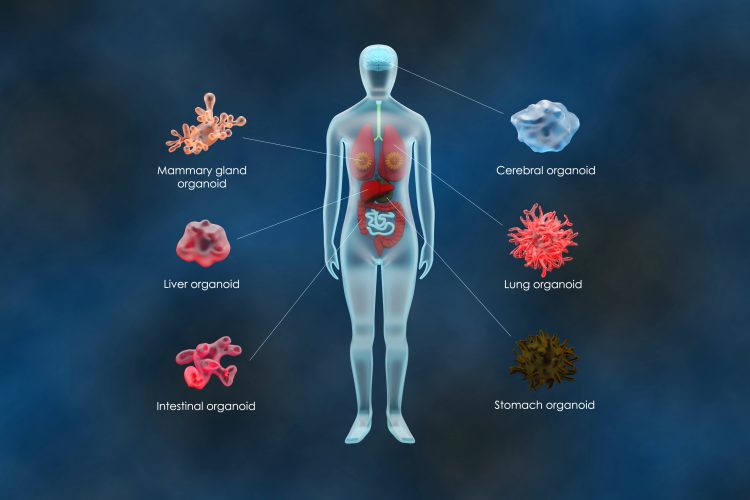

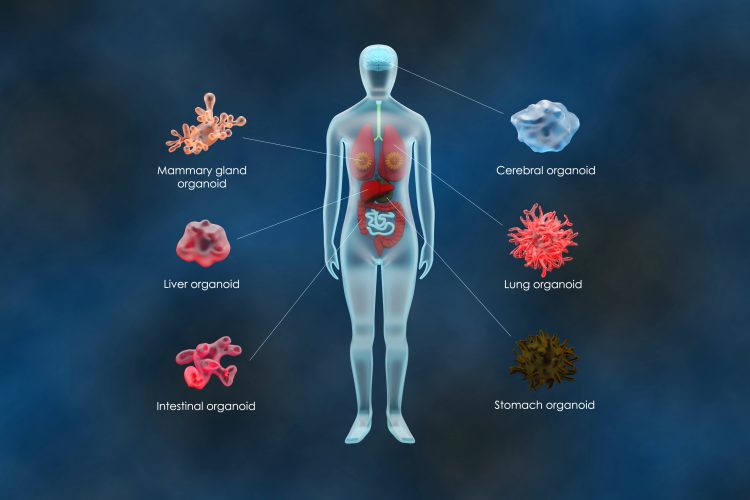

Organoids are changing the landscape of biomedical research, with automation and AI driving new levels of consistency, scalability and human relevance. Aaron Risinger of Molecular Devices discusses how these technologies are advancing precision medicine – and the challenges that remain.

The life sciences industry is quickly moving toward more personalised treatments, with organoid technology playing an increasingly important role in advancing precision medicine.

These three-dimensional, self-organising cell cultures have the potential to better reflect human biology, providing a more accurate platform to study disease and test therapies. To explore how automation and AI are transforming this space, we spoke with Aaron Risinger, Director of Business Development at Molecular Devices, who discussed the challenges, opportunities and technological advances shaping the next era of biomedical research.

Defining organoids and their promise for precision medicine

“The term ‘organoid’ gets used in all sorts of ways,” Risinger explained. “To help bring a little more clarity, the US Department of Commerce’s National Institute of Standards and Technology (NIST) is working on setting definitions for new and emerging areas in biotechnology. I’ve had the chance to join a team of technology experts contributing to how organoids are defined for NIST.”

Patient-derived organoids, in particular, hold promise for precision medicine because they retain the genetic and phenotypic diversity of the original tissue, including tumours.

According to Risinger, the consensus is that organoids are “a specialised class of cellular models that can self-organise into tissue-like structures containing multiple relevant cell types from the tissue they represent.” This structural and cellular complexity distinguishes them from simple spheroids or single-cell-type cultures.

Patient-derived organoids, in particular, hold promise for precision medicine because they retain the genetic and phenotypic diversity of the original tissue, including tumours. “By testing drugs against these more physiologically relevant models before clinical trials, we should theoretically see better prediction of human responses and potentially higher success rates for precision medicine approvals,” he said.

At Molecular Devices, Risinger’s focus lies in espousing the tools that make organoid research scalable and consistent. These systems produce assay-ready organoids to help researchers run sensitivity tests across multiple conditions at scale.

Why automation is essential for organoid workflows

Organoids offer exciting biological insight, but they’re also complex to work with. “Unlike traditional cell lines, which might need attention every two to three days, organoids sometimes require monitoring and feeding at six- and eight-hour time points, particularly during critical differentiation stages,” said Risinger.

That intensity makes manual workflows unsustainable and unscalable. “This is where automation becomes essential. Not because it’s faster, but because it’s consistent, leading to better reproducibility. They do it the same way every time.”

Automation allows researchers to build reproducible datasets across diverse samples – which are vital for translating personalised insights into scalable drug discovery.

“In order to automate high-throughput drug screening across organoid models that reflect real-world patient diversity, you need significant amounts of the organoid models themselves – requiring automated cell culture techniques on the front end of experimentation,” Risinger said. “This will enable multi-omic approaches that integrate genomic, proteomic and phenotypic screening data.”

The advantage of human-relevant models

Animal models have long been a staple of preclinical testing, but organoids are proving to be a more human-relevant alternative. Although animal models can reveal key details about how a drug functions in a living organism, they still differ significantly from humans. “Even as you move towards simian models, which are much closer to humans, there are still significant differences,” Risinger said.

Animal models have long been a staple of preclinical testing, but organoids are proving to be a more human-relevant alternative.

With drug candidates failing at a rate of around 90 percent in late-stage clinical trials, this difference has major implications.

“Organoids are more physiologically relevant because they’re derived from human cells and maintain the complexity of human tissues, including genetic, epigenetic and functional characteristics,” he explained. “The goal isn’t necessarily to replace animal models entirely, but to refine and reduce their use.”

A regulatory shift away from animal models

Recent policy developments are now accelerating a transition away from animal models. In April 2025, the FDA and NIH started the process toward this transition.

“The FDA announced plans to phase out animal testing requirements for drugs like monoclonal antibodies, building on the FDA Modernisation Act 2.0,” Risinger said. “The NIH committed to prioritising funding for non-animal research technologies.”

These initiatives are expected to drive the rapid adoption of organoid-based model systems.

“Researchers seeking NIH funding are now incentivised to adopt 3D biology technologies, which should drive industry-wide changes in both academic research and pharmaceutical development,” he explained.

Preparing researchers for the transition

Molecular Devices is actively supporting scientists through this shift by developing automated systems such as the CellXpress.ai® Automated Cell Culture System and 3D Ready™ Organoids.

“These are reliable options for researchers eager to use physiologically relevant, patient-derived organoid models without lengthy culturing processes,” said Risinger.

The company’s bioprocess technology enables large-scale production of consistent organoids. “Using continuous perfusion, we can generate large batches of patient-derived organoids – ranging from 6 to 15 million in a single batch – all at the same passage,” Risinger explained. “Whether you use vial one today or vial 20 two months later, you’ll have the same material at the same passage.”

“This industrialised approach is what researchers need to confidently transition away from animal models,” he added.

How automation and AI enable 24/7 organoid growth

Automation doesn’t just mean speed – it means precision too. While the new robotic elements aren’t necessarily faster than manual processes, they make the work more reproducible.

New automated systems such as CellXpress.ai operate around the clock, minimising manual cell culture labour and reducing strain on researchers.

“They perform the same procedures the same way every time, which dramatically improves consistency,” said Risinger.

New automated systems such as CellXpress.ai operate around the clock, minimising manual cell culture labour and reducing strain on researchers.

“We’re enhancing experimental consistency while also significantly improving quality of life for those doing the research,” Risinger said.

The role of machine learning in organoid analysis

Machine learning now supports organoid research at multiple levels – from automated image segmentation to real-time culture decisions.

“What’s really interesting is that the algorithms now being branded as ‘AI’ have been at work in high-content screening and cell analysis for more than a decade,” Risinger noted. “In our automated cell culture system, AI interprets this data to make real-time decisions about when to feed, passage, or add specific growth factors.”

Together, these systems transform subjective judgment into hard data – producing a traceable fingerprint of healthy cell behaviour and revealing when something goes off track.

Imaging: seeing inside complex 3D structures

To understand these intricate structures, advanced imaging systems are essential. These imaging platforms serve as the visual interface for AI-driven decision-making in modern cell culture workflows.

“We employ rapid widefield detection to monitor the cell journey and complement it with endpoint analysis using high-throughput confocal imaging with advanced lasers.” He continues, “this combination enables detailed 3D imaging of organoids at high speed and resolution, penetrating deep into organoid tissues to reveal cellular interactions and structures that traditional 2D workflows might otherwise miss.”

From complex images to usable drug data

AI-powered software transforms large imaging datasets into actionable insights. Complex analysis tools now use state-of-the-art AI algorithms to extract information from raw microscopy images. Without these systems, it would be impossible to interpret high-dimensional biological data at the required scale.

Risinger says that by automating segmentation, clustering and interpretation, the software “reduces human bias, improves reproducibility and accelerates the identification of promising compounds.”

The path ahead for organoids and precision medicine

Looking ahead, Risinger sees both challenges and opportunities in scaling organoid research, the greatest of which is ensuring reproducibility and standardisation. “There are so many different ways that people are currently manually creating organoid systems and that’s inherent in any emergent field,” he said.

There are so many different ways that people are currently manually creating organoid systems and that’s inherent in any emergent field.

If achieved, the rewards could be transformative for drug discovery and the life sciences industry as a whole.

“Imagine a scenario where your specific disease state, captured through a biopsy, can be cultured, expanded and used for frontline drug sensitivity testing,” he said. “As we continue to evolve these tools and make them faster, we’ll move closer to a future where patient biopsies could be rapidly cultured and tested against available therapies to guide frontline treatment decisions.”

“The progress is accelerating,” he concluded. “We’re not there yet, but the technology is evolving quickly and I’m optimistic about the impact it will have.”

Aaron Risinger

As the Director of Business Development for Cellular Workflow Automation at Molecular Devices, Aaron is responsible for fostering collaborations and strategic partnerships to drive the commercial success of our Cellular Workflow and Automation business unit. This includes the development, scale-up, and manufacturing of patient-derived organoids (PDOs) and cutting-edge technologies like the CellXpress.ai® Automated Cell Culture System.

With over two decades of experience in the life sciences, Aaron actively collaborates with academic institutions, research organizations, and pharmaceutical companies to drive innovation in 3D biology. He holds a Biochemistry degree from Texas A&M University and an MBA from The University of Texas, San Antonio.

Related topics

Artificial Intelligence, Cell Cultures, Drug Discovery Processes, Lab Automation, Organoids, Precision Medicine, Translational Science

Related organisations

Molecular Devices