Finding the right CDMO partner for cell line development

Posted: 5 April 2024 | Dr Séverine Fagète (Mammalian Cell Line Development) | No comments yet

The commercial production of recombinant proteins, such as antibodies and enzymes, relies on generating and maintaining specific cell lines designed to produce these specialised molecules. However, the creation of cell lines is a technically demanding and time-consuming process. For this reason, many businesses seek partnerships with contract development and manufacturing organisations (CDMOs) for their cell line development (CLD) needs. This partnership is not a decision to be made lightly, as companies need a stable, high-quality cell line to take their protein from the development phase to commercialisation. In this article, we’ll outline the signs that a CDMO is the right fit for a company’s CLD partnership.

They appreciate and understand the host cell background

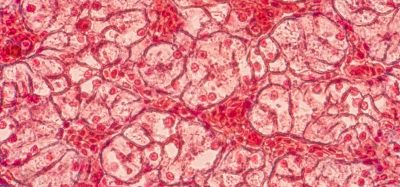

A large majority of clinical and commercial proteins are generated in Chinese hamster ovary (CHO) cells. The dominance of CHO cells within the biopharma industry is a result of several beneficial characteristics displayed by these cells, including reduced susceptibility to human viruses, robust ability to proliferate on a large scale, amenability to suspension cultures, and ability to perform post-translational modifications similar to those found on the native protein. Together, these attributes provide a strong foundation for protein expression with enough adaptability to produce much of the commercial and therapeutic protein market.

However, there is significant variability within the various CHO cell lines, and CDMOs often have differing levels of success in optimising their cells for protein production. For example, a CDMO with deep sequencing knowledge and a proprietary cell line will achieve significantly better performance than CDMOs that license third-party technologies. A thorough understanding of the genome and epigenome allows CDMOs to insert the transgene of interest into genomic regions that are highly expressed, increasing overall protein production. Skilled CDMOs can also locate or create favourable genomic microenvironments where transcription factors are efficiently recruited, further boosting protein production. Finally, comprehensive genetic knowledge also facilitates the use of powerful bioinformatic tools that strengthen the cell-line development process, especially for enhanced protein expression or monoclonality assessment. Therefore, the depth of knowledge a CDMO has on their cell lines is an essential factor for biopharmaceutical companies to consider when searching for a protein production partner.

They’re prepared for complexity

Successful expression of the gene of interest is not sufficient on its own for large-scale production. Following mRNA translation into the corresponding amino acid sequence, a variety of linkages, cleavages, and chemical modifications must occur for a protein to be functional. Collectively, these alterations are referred to as post-translational modifications (PTMs). One of the challenges of manufacturing biologics is that PTMs are highly individualised to each protein, yet vital to its functionality. To accommodate this demand, it’s important to identify CDMOs capable of tailoring their cell-line development process to the unique requirements of the molecule. In addition to being adaptable, the CLD process should also be fully integrated with other components of the CDMO, such as analytics or formulation development, to limit tech transfers and streamline development.

This is especially true for bispecific proteins, a rapidly evolving class of structurally complex therapeutics. Bispecific proteins are primarily heterodimeric, which adds additional complexity to the production process, as homodimeric configurations must be minimized and removed from the final formulation. CDMOs should be prepared to offer solutions at the early stages of the CLD process that ensure heterodimeric, bispecific protein production is fine-tuned to generate high-quality therapeutics.

Proteins can also aggregate or be degraded and fragmented by reactions occurring within the cell culture or the protein purification process. These unwanted alterations can adversely affect the protein’s stability, immunogenicity, and functionality. A good CDMO can offer customised solutions, such as chaperone proteins, to facilitate the production of even the most challenging protein. For these reasons, biopharma companies should seek out CDMOs willing to design a tailor-made approach to cell line development so that they can be confident protein production will not be impeded by unforeseen complexity.

They understand the importance of safety

There are two types of contamination that biopharmaceutical companies must consider when selecting a CDMO. The first concern is microbial contamination. Since cells must be grown in a nutrient-rich environment, rigorous processes are paramount to avoid introducing fungus, bacteria, or viruses to the system. CDMOs must routinely test throughout CLD to ensure cell cultures are free of microbes. The importance of high-caliber quality control within a CLD facility cannot be overstated.

Contamination can also refer to impurities within the cell line and expressed protein. For instance, monoclonal antibodies not produced from a single progenitor cell or mixed with another antibody are considered contaminated. A good CDMO should have well-defined separations between CLD processes to prevent cross-contamination. CDMOs can also perform genetic and molecular tests to confirm that the correct molecule is being produced and that the cell line is derived from a single-parent cell. The safety of a biopharmaceutical product is of the utmost importance, and companies should ensure they are partnering with a CDMO that takes contamination issues as seriously as they do.

They’re good communicators

The aforementioned areas of scientific expertise will be crucial in determining which CDMO a company should partner with. Still, it’s important not to overlook the human element. Biopharma companies are making a serious investment in their future when choosing a CLD collaborator, and as such, they should seek a CDMO with the highest quality customer service. The ability to discuss concerns with subject matter experts, receive guidance on regulatory compliance, and establish a productive working relationship with a project manager are all important components of a successful partnership.

Finding the right CDMO may require significant time and company resources, but CLD sits at the heart of biologics development. It’s important that companies find organisations with extensive expertise in CLD so that any regulatory milestone or scientific hurdle can be passed with ease. The upfront investment in identifying a high-quality CDMO will pay dividends with a stable, high-quality cell line that companies can feel confident going to market with.

About the author

Vice President, Mammalian Cell Line Development

Séverine is the Vice President of Mammalian Cell Line Development (CLD) at KBI Biopharma’s Geneva Facility. Prior to the operational consolidation with KBI, Séverine held multiple leadership roles with escalating responsibilities at Selexis. She brings nearly two decades of experience in the pharmaceutical industry, and deep expertise in early drug discovery, antibody engineering (bispecifics), stable cell line development, and project management.

Séverine holds a master’s in biotechnology from L’Ecole Nationale Supérieure de Technologie des Biomolécules de Bordeaux (ENSTBB) and a PhD in protein engineering from University of Geneva, acquired through NovImmune (now Light Chain Bioscience). She subsequently held a postdoctoral position at the University of Geneva where she designed a novel phage display platform for accelerating bispecific antibody development.

Related topics

Cell Line Development, Cell Regeneration, Cell Therapy, Cell-based assays

Related organisations

Mammalian Cell Line Development

Related people

Dr Séverine Fagète (Mammalian Cell Line Development)