Driving efficiency across upstream bioprocess workflow

Posted: 15 March 2024 | Dr Anis H Khimani (Revvity) | No comments yet

Dr Anis H Khimani from Revvity explores how key developments have enhanced biotherapeutic workflows, and explores how a transposon system can aid stable clone development.

The discovery and development phases of biotherapeutic drugs leverage multiple technologies and processes across upstream and downstream stages of the bioprocess workflow. Advancements in cell line development (CLD), including screening and selection of final clones, scale up, automation and digitalisation have enabled precision and enhanced productivity. Efforts have focused on Chinese hamster ovary (CHO) cell line improvements since it is a commonly used host for the expression of therapeutic proteins. This article will focus on a novel transposon system for stable clone development with low variation.

Emerging novel approaches to enable the workflow

The development of biotherapeutic molecules has evolved significantly over the past two decades. Advancements in genetic and protein engineering through technology innovation, automation, and more recently machine learning, have led to the development of more complex molecules such as bispecific antibodies and antibody drug conjugates.

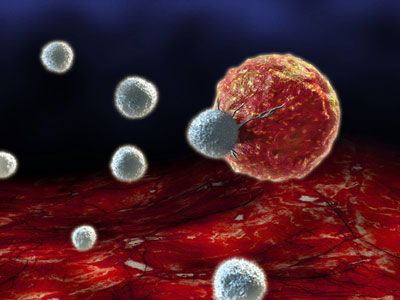

Selecting the appropriate upstream tools is key to avoiding challenges downstream, ultimately reducing development costs and delays in drug approvals. Variability during cell line development can occur after transfection through random genetic integration in host cells that can lead to clonal heterogeneity and instability of the transgene(s). Establishing stable, high yield clones with maximum homogeneity earlier in the process is critical to facilitate clone expansion and scale up.

Technology advancements have enabled a significantly more streamlined and efficient cell line development process. Novel engineering tools, such as gene editing, have facilitated knock-out cell lines with enhanced characteristics. For example, the engineering of commonly used CHO cells for various metabolic pathways has delivered improved expression levels of large molecule drugs and subsequent enhanced product quality.1,2 Enhancement of such expression platforms via novel transposon approaches has led to the generation of stable, homogenous clones expressing high yields of protein.

Transposon technologies are gaining traction due to their accuracy in integrating the gene of interest into the host genome, making them an important tool for accelerating large molecule drug development. Transposons preferentially integrate the gene of interest into active transcriptional sites, facilitating rapid cell line development and higher titers of the protein drug.3 The use of transposon-based systems significantly reduces risks of integrating bacterial elements present on the transposon vector, since integration of the gene is catalysed by the transposase only upon recognition of the inverted terminal repeats (ITRs) flanking the gene of interest and the selection cassette. The expression system can help to improve reproducibility between different transfections, and thus also help improve clone stability.4

Among various transposon approaches, a recently developed vector system enables multi-copy, non-fragmented gene cassette integration.5 This strategy results in clonal stability of >95 percent at both genetic and phenotypic level, significantly reducing clone screening efforts and thus streamlining process development.6 The two-component system comprises a transposon vector and a transposase, preferably in the form of mRNA, which can be co-transfected into CHO cell lines. The mRNA is then translated into transposase protein, which catalyses transgene excision and integration into the CHO host genome. An advantage of this system is that it allows for intact integration of the expression cassette at each integration site, unlike random integration approaches that may lead to fragmentation, rearrangement, or concatemerisation of the gene of interest. Subsequently, stable clones are screened, identified and characterized, leading to clonal cell banks for GMP production of the drug product.

Future directions

Over the past couple of decades, technologies and process development have driven significant advancement in large molecule biotherapeutic drug development via streamlined workflows, establishment of critical quality attributes (CQAs), and eventually compliance with regulatory requirements. Across the bioprocess workflow, specific development focuses on upstream cell line development as this founding step results in protein-producing clones and establishes criteria leading to higher titers and subsequent potential scale up.

As discussed above, recent advances in gene editing tools and transposon-based vectors have facilitated targeted and consistent cell line engineering for the development of protein expressing CHO cell lines. Furthermore, adoption of automated and standardised cell counting and clone selection technologies can help optimise cell line development workflows. In addition, machine learning can potentially provide predictive models to assist in reducing process gaps and enhance productivity. A collaborative strategy and integration of systems across functional areas can lead to a next-generation model workflow.

Disclaimer: For research use only. Not for use in diagnostic procedures

About the author

© 2023 KP Visions #Revvity

Dr Anis H Khimani

Senior Strategy Leader, Life Sciences strategy group, Revvity, Inc.

Anis works within the strategy group in Life Sciences at Revvity, Inc. With more than 20 years of experience in business management, strategy, marketing and product management, Anis also has a research background in biotech, pharmaceutical and premier academic organisations. He has a post-doctorate in virology, viral pathogenesis, viral vector development, and vaccines evaluation from Harvard Medical School, and a PhD in virology/molecular biology. Anis also serves on the scientific and editorial advisory board of Genetic Engineering News at Mary Ann Liebert, Inc.

References

- Mistry RK, Kelsall E, Sou SN, et al. 2021. A novel hydrogen peroxide evolved CHO host can improve the expression of difficult to express bispecific antibodies. Bioeng., 118:2326.

- Budge JD, Knight TJ, Povey J, et al. Engineering of Chinese hamster ovary cell lipid metabolism results in an expanded ER and enhanced recombinant biotherapeutic protein production. Metab. Eng. 57:203.

- Wright C, Alves C, Kshirsagar R, et al. Leveraging a CHO cell line toolkit to accelerate biotherapeutics into the clinic. Biotechnol Prog. 2017 Nov;33(6):1468-1475. doi: 10.1002/btpr.2548. Epub 2017 Sep 7. PMID: 28842948.

- Narayanavari SA, Izsvák Z. 2017. Sleeping Beauty transposon vectors for therapeutic applications: advances and challenges. Cell Gene Therapy Insights 2017; 3(2), 131-158, 10.18609/cgti.2017.014.

- Patel T, Ingham C, Fleming J, et al. 2022. CHOSOURCE™ ADCC+ cell line for enhanced therapeutic potency. https://horizondiscovery.com/-/media/Files/Horizon/resources/Posters/chosource-chok1-adcc-cell-line-poster.pdf

- Surve T, Rebocho A, Fleming J, et al. 2022. Integration of next-generation transposon vectors with novel host cell lines. https://horizondiscovery.com/ /media/Files/Horizon/resources/Posters/chosource-tnt-poster.pdf

Related topics

Cell Line Development, Cell Regeneration, Cell Therapy, Cell-based assays

Related organisations

Revvity

Related people

Dr Anis H Khimani (Revvity)