Smart automation for every lab, not just big pharma

Posted: 10 July 2025 | Drug Target Review | No comments yet

Drug Target Review spoke with Giancarlo Basile at SLAS Europe 2025 about MGI’s bold shift from sequencing specialist to automation partner – helping research companies of all sizes achieve accuracy, speed and reproducibility.

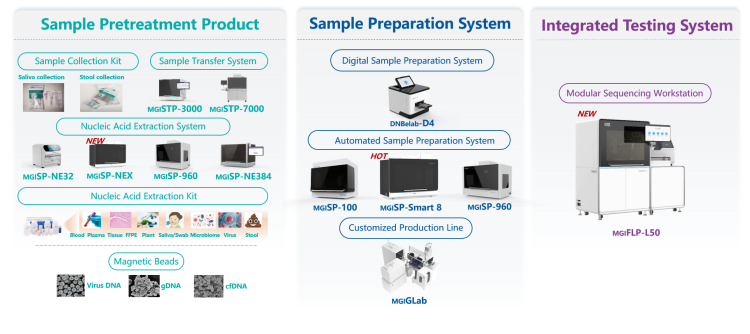

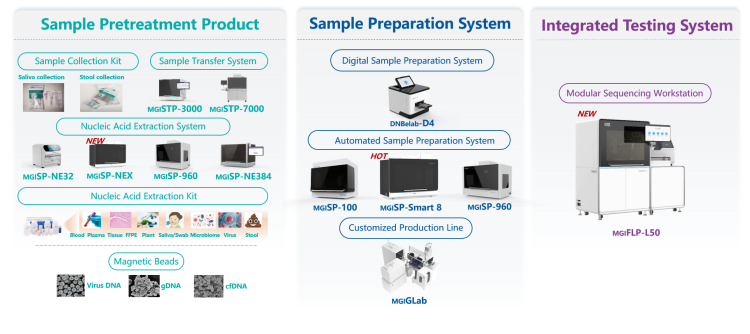

MGI is best known for its contributions to the genomics sector. Its core business has focused on sequencing platforms, along with the reagents and consumables used in sample preparation and library construction – all of which have played a central role in making next-generation sequencing (NGS) more accessible globally.

“So far, MGI is a sequencing company. We manufacture sequencing platforms, reagents and consumables,” confirms Giancarlo Basile, Head of the Automation Sales Department of MGI Europe & Africa.

Yet as sequencing applications expanded – particularly in population genomics, precision medicine and diagnostics – so has the demand for automation to streamline sample preparation and data generation workflows. MGI responded with automation platforms that complemented its sequencing systems, handling tasks such as library preparation and nucleic acid extraction. “Automation was essentially a complement of our sequencing platforms,” Basile added. “For library preparation and various extraction steps.”

Automation now plays a central role in discovery. From self-driving laboratories to real-time bioprocessing

This report explores how data-driven systems improve reproducibility, speed decisions and make scale achievable across research and development.

Inside the report:

- Advance discovery through miniaturised, high-throughput and animal-free systems

- Integrate AI, robotics and analytics to speed decision-making

- Streamline cell therapy and bioprocess QC for scale and compliance

- And more!

This report unlocks perspectives that show how automation is changing the scale and quality of discovery. The result is faster insight, stronger data and better science – access your free copy today

Expanding beyond NGS

While its automation had been tightly coupled to MGI’s sequencing systems, the company began to realise that its platforms had broader potential. As new instruments were developed – such as MGISP-Smart 8 and PrepALL – it became clear that their flexibility could serve a wider array of research needs.

“The products that we have introduced recently are very flexible platforms,” said Basile.

Recognising this potential, MGI made a strategic decision to diversify the application of its automation technologies. “The idea was [to] capitalise on this flexibility and try to expand the business to areas that are currently outside next-generation sequencing”

This marked a significant shift for the company, which began building out eco-partners focused not on genomics, but on developing custom solutions for diverse research areas including cell biology, proteomics, mass spectrometry and drug discovery.

Laying the groundwork for expansion

This transition did not happen overnight. MGI invested significant time and resources to establish internal capabilities for custom automation. This meant recruiting staff, setting up workflows and implementing development processes suited to customer-specific needs.

“We took time to hire people, assemble the team, build the processes within the organisation,” said Basile, referring to the groundwork needed to support customers outside of genomics.

One key initiative was the creation of internal documentation and operational expertise tailored to customised automation. These efforts ensured the company could deliver bespoke solutions while maintaining quality, scalability and cost-efficiency.

“We started to build documentation and the expertise within the organisation here in Europe,” Basile added.

MGI’s automation solutions: Streamlining the entire genomic workflow.

Building an automation ecosystem

Basile was keen to emphasise that automation is not just about moving liquids.

“Liquid handling is just a part – you’re just moving liquids. But this is not enough,” he said. “It’s just a piece of what the customer needs.”

To build full workflow solutions, MGI began establishing a far-reaching network of technology partners. This ecosystem now includes more than 40 collaborators across Europe and America, ranging from microplate reader manufacturers to specialists in imaging, incubation and environmental control. “One of the activities that we implemented was to establish an ecosystem of partners. We contacted different companies specialised in specific segments to collaborate together,” Basile explained.

This collaborative model allows MGI to quickly assemble tailored workflows for complex customer challenges. For instance, when a client needs both an automated liquid handler and a compatible microplate reader, MGI can draw on pre-established partnerships to integrate the full solution.

A structured approach to customisation

One of the defining elements of MGI’s strategy is what Basile calls “democratising customisation.” Custom lab automation, particularly in pharma and biotech, has historically been costly and complex. MGI is seeking to make it more accessible.

“Customisation is complex and expensive. Not all potential customers can access it,” said Basile. “But we are very good at customisation and can provide cost-efficient solutions.”

The company follows a structured, collaborative process to ensure that each solution fits the customer’s needs. It begins with a User Requirement Document, wherein the customer outlines the goals, constraints and desired outcomes of the project.

Customisation is complex and expensive. Not all potential customers can access it.

“The customer writes down their needs – some of which are very technical – but it helps define the space,” Basile explained.

From there, MGI’s multidisciplinary team – spanning hardware, software and application development – analyses the information and prepares a Project Specification Document. This document outlines the technical, operational and financial dimensions of the proposed solution.

“It includes not only the technical parts, but also the consumables, time for installation, and everything needed for project success.”

Embedded collaboration

To ensure these projects succeed in real lab environments, MGI invites customers to its Customisation Experience Centre in Berlin, where they can test and review automation setups on-site. The team also visits customer labs to gain a deeper understanding of current workflows and bottlenecks.

Sometimes, customers struggle to explain their manual workflow. By visiting them, we can observe what’s actually happening and better understand how to automate it.

“Sometimes, customers struggle to explain their manual workflow,” Basile said. “By visiting them, we can observe what’s actually happening and better understand how to automate it.”

This real-world collaboration allows MGI to iterate quickly and make practical modifications. Basile described one case where visiting a customer’s lab led to a rethink of the workflow that wasn’t captured on paper.

“It was painless for us and valuable for the customer because we became more aligned with the real situation.”

Why automation matters – even at low throughput

Basile also addressed a common misconception: that automation is only worthwhile for high-throughput labs. Reproducibility and precision matter just as much in small-scale workflows – particularly when working with precious samples or expensive reagents.

“Maybe you’re working with two samples, but you need accuracy; maybe you’re working with very rare cells or expensive reagents,” he said. “Automation gives you peace of mind. The instrument does the same thing, the same way, every time.”

He used a relatable example: “If you’re working with primary cells and your phone rings while pipetting manually – you’ve lost the sample. That’s a problem.”

New application areas

In addition to genomics, MGI is expanding into several high-impact research areas where automation can reduce variability and improve reproducibility:

- Organoids and 3D cell models:

“It’s very difficult to control the biology when generating spheroids. Having a robotic arm doing the same thing every time reduces variability.”

- Lipidomics and MALDI spotting:

“You have a relatively low number of samples, but you must be precise in how they’re handled.”

Each of these fields benefits from automation, not because of scale, but because of the need for consistency and accuracy.

Sustainability and digitalisation

In line with global lab trends, MGI is also considering how to make automation more sustainable.

The company is exploring plastic recycling initiatives and working with partners to reduce single-use consumables. Digitalisation is another future goal, integrating data-driven workflows to improve traceability and efficiency.

Conclusion: customisation for all

MGI’s strategy to expand beyond sequencing is driven by a simple idea: to bring flexible, reproducible automation to a broader range of scientists and labs, regardless of size or budget. With structured development processes, a strong partner ecosystem and a commitment to co-creation, the company is positioning itself as more than a technology vendor – it’s becoming a customisation partner.

“We will never ask customers to adapt their workflow to fit our product,” Basile said. “We adapt our solutions to fit them.”

Giancarlo Basile is the Head of the Automation Sales Department at MGI for Europe and Africa. With over 25 years of experience in R&D sales and business development, he has held key roles at leading companies in the life sciences and medtech sectors, including Hamilton, Tecan and Lexogen. In addition to his commercial expertise, Giancarlo also served as Editor-in-Chief of Molecular Biotechnology, a journal published by Springer Nature.

Related topics

Drug Discovery, Drug Discovery Processes, Lab Automation, Lipidomics, Mass Spectrometry, Next-Generation Sequencing (NGS), Organoids, Precision Medicine, Sequencing

Related organisations

MGI