Self-assembling biomaterial could be used to model vascular structures

Posted: 5 March 2020 | Hannah Balfour (Drug Target Review) | No comments yet

Scientists have shown an innovative new biomaterial made of graphene oxide and proteins could be used to 3D print model vascular structures.

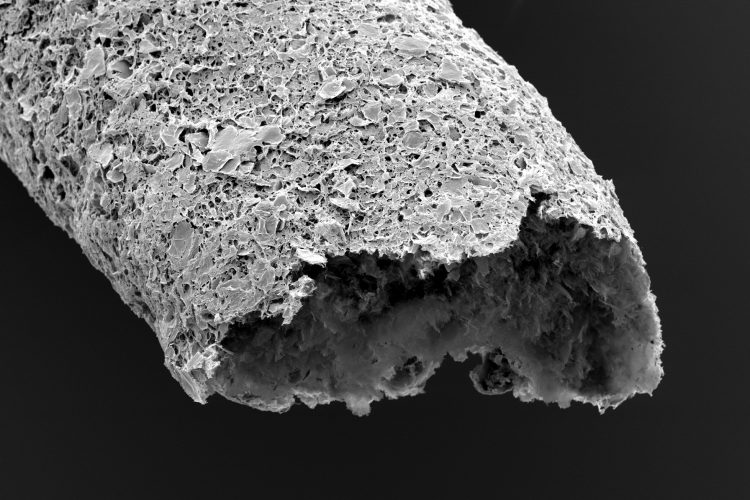

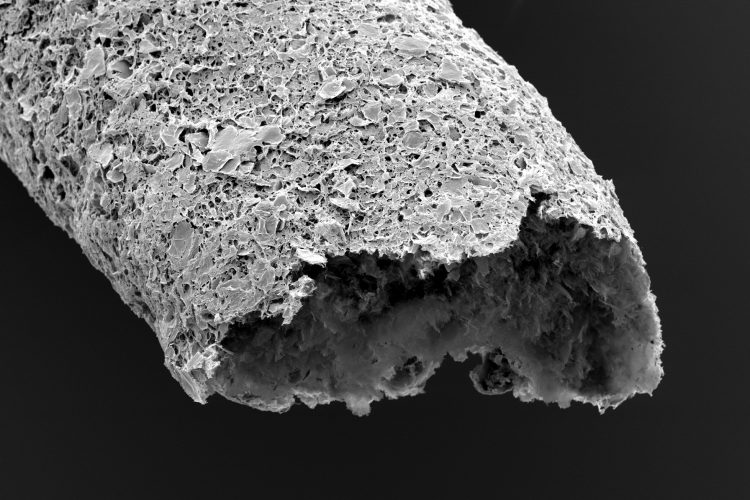

Close-up of a tubular structure made by simultaneous printing and self-assembling between graphene oxide and a protein (credit: Professor Alvaro Mata).

Researchers have developed a technique through which they can three-dimensionally (3D) print tubular structures that can replicate properties of vascular tissue. The team suggest the 3D printed biomaterial could be used to model vascular diseases and develop new therapeutics.

This could enable the recreation of vasculature in the lab and have implications in the development of safer and more efficient drugs”

The study published in Nature Communications shows that a mix of graphene oxide and protein can self-assemble into a biomaterial able to grow, replicate and possibly withstand the flow of liquids. According to the collaborators from the University of Nottingham and Queen Mary University London, both UK, the mechanism of self-assembly allows the flexible regions of proteins to conform to graphene oxide, generating strong interactions able to be scaled to multiple sizes in the presence of cells.

Once self-assembled, the biomaterial can be used as a 3D printing bio-ink to create structures at the nanoscale.

Study leader, Professor Alvaro Mata, from the University of Nottingham said: “This work offers opportunities in biofabrication by enabling simulatenous top-down 3D bioprinting and bottom-up self-assembly of synthetic and biological components in an orderly manner from the nanoscale. Here, we are biofabricating micro-scale capillary-like fluidic structures that are compatible with cells, exhibit physiologically relevant properties and have the capacity to withstand flow. This could enable the recreation of vasculature in the lab and have implications in the development of safer and more efficient drugs, meaning treatments could potentially reach patients much more quickly.”

Dr Yuanhao Wu, the lead researcher on the project, said: “There is a great interest to develop materials and fabrication processes that emulate those from nature. However, the ability to build robust functional materials and devices through the self-assembly of molecular components has until now been limited. This research introduces a new method to integrate proteins with graphene oxide by self-assembly in a way that can be easily integrated with additive manufacturing to easily fabricate biofluidic devices that allow us replicate key parts of human tissues and organs in the lab.”

Related topics

3D printing, Bioengineering, Bioprinting, Disease Research, Nanotechnology, Protein, Technology

Related conditions

vascular disease

Related organisations

Nottingham University, Queen Mary University London

Related people

Dr Yuanhao Wu, Professor Alvaro Mata