3D printing ‘bio-ink’ developed for regenerative medicine

Posted: 11 February 2020 | Victoria Rees (Drug Target Review) | No comments yet

Using modified hyaluronic acid and polyethylene glycol, researchers have created a bio-ink for 3D printing, which could be used as a scaffold to grow human tissues.

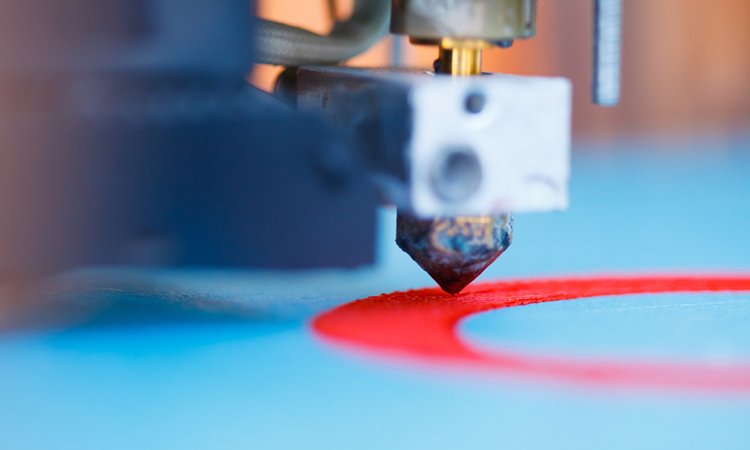

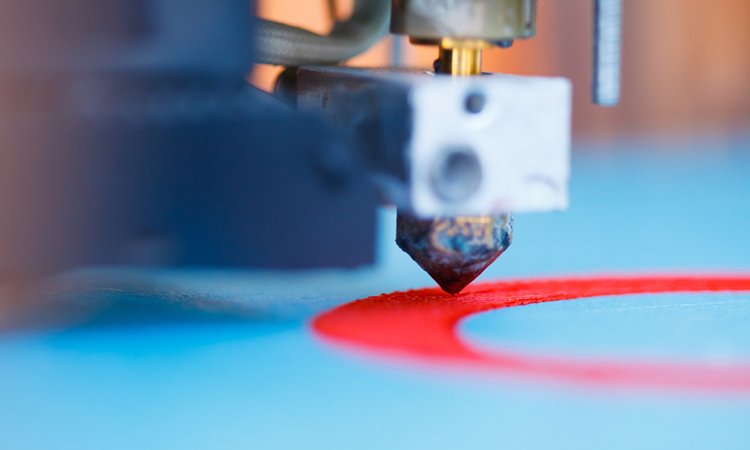

Researchers have developed a ‘bio-ink’ for three-dimensionally (3D) printed materials that they say could one day serve as scaffolds for growing human tissues to repair or replace damaged ones in the body.

From Rutgers University, US, the scientists explain that bioengineered tissues show promise in regenerative, precision and personalised medicine, as well as product development and basic research.

Previous studies have shown that hyaluronic acid, which is a natural molecule found in many tissues throughout the body, has many properties ideal for creating customised scaffolds, but lacks the necessary durability for tissues. Instead, the Rutgers engineers used modified versions of hyaluronic acid and polyethylene glycol to form a gel that was strengthened via chemical reactions and would serve as a scaffold.

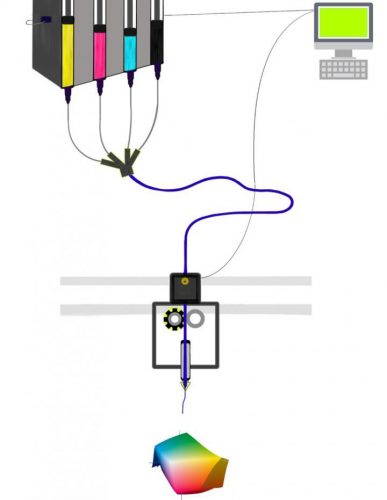

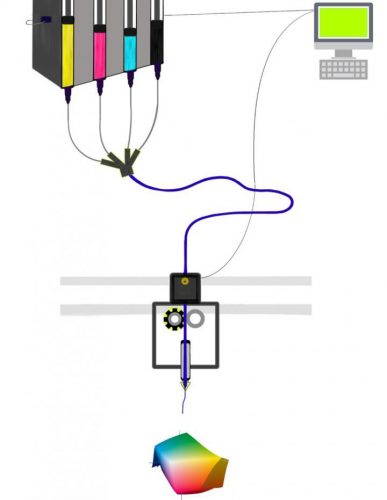

This 3D printing system would print gel scaffolds, or support structures, for growing human tissues. Like traditional printers that rely on four pigments to cover the entire color spectrum, the system would include hyaluronic acid and polyethylene glycol as the basic “ink cartridges” and other cartridges featuring inks with different cells and ligands that serve as binding sites for cells (credit: Madison Godesky).

“Instead of an ink colour for an inkjet printer, we want the mixture to have properties that are right for specific cells to multiply, differentiate and remodel the scaffold into the appropriate tissue,” said senior author David Shreiber, a professor who chairs the Department of Biomedical Engineering in the School of Engineering at Rutgers University-New Brunswick. “We focus on the stiffness of the gel and scaffold binding sites that cells can latch onto.”

The functional effects of the tuneable mechanical and bioadhesive ligand properties were confirmed with assays of cell adhesion and morphology.

The researchers envision a system where hyaluronic acid and polyethylene glycol serve as the basic “ink cartridges” for 3D printing. The system would also have other ink cartridges featuring different cells and ligands, which serve as binding sites for cells. They theorise this method would print gel scaffolds with the right stiffness, cells and ligands, based on the type of tissue desired.

“Both the stiffness and the binding sites provide important signals to cells,” lead author Madison Godesky said. “What especially distinguishes our work from previous studies is the potential to control the stiffness and ligands independently through combinations of inks.”

The study was published in Biointerphases.

Related topics

3D printing, Cell-based assays, Disease Research, Regenerative Medicine, Research & Development

Related organisations

Rutgers University-New Brunswick

Related people

David Shreiber, Madison Godesky