Not everyone loves surprises: know your ADC’s critical quality attributes

Posted: 26 March 2020 | Martin De Cecco (Merck), Omar Lamm (MilliporeSigma) | No comments yet

The importance of product characterisation throughout the entire drug development process cannot be understated. Success, money and lives depend on it. This article delves into why you need to understand every aspect of an ADC in order to prevent unwelcome surprises down the line.

THE INCREASED industry-wide focus on cancer, due to its rising patient population and a surge in cancer research, has resulted in an explosion of novel therapeutic drugs to treat this tenacious disease. The highly targeted approach of antibody drug conjugates (ADCs), where an antibody is connected to an antitumour cytotoxin via a linker, has been extremely effective in treating various types of cancer.

The success of ADCs has made them the fastest growing class of oncology therapeutics with an expected global market value of $7.5 billion by 2025.¹ Yet, the intrinsic complexity of developing and manufacturing ADCs creates major challenges when trying to bring these life-saving therapies to market. Combatting many of these obstacles requires robust product characterisation throughout all phases of development, as small changes can have a big impact, ultimately affecting the success of the final product. Through early identification and a deeper understanding of a drug’s critical quality attributes, you can move to clinical trials faster, confident that you are producing a drug with the highest level of safety and quality.

Understanding the structure of your ADC

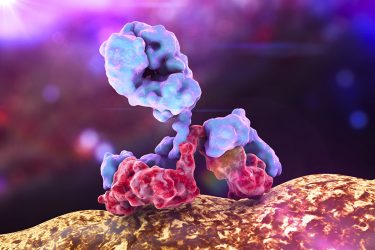

The functionality of an ADC relies predominantly on the ability of an antibody to deliver a cytotoxin, or payload, directly to its intended target, which then kills the cancer cells upon internalisation. The antibody also has the potential to recruit immune cells via Fc receptor binding. Although this can be helpful in a patient’s fight against cancer, it could also stimulate an immune response that damages healthy cells and causes unwanted side effects.

The functionality of an ADC relies predominantly on the ability of an antibody to deliver a cytotoxin, or payload, directly to its intended target, which then kills the cancer cells upon internalisation. The antibody also has the potential to recruit immune cells via Fc receptor binding. Although this can be helpful in a patient’s fight against cancer, it could also stimulate an immune response that damages healthy cells and causes unwanted side effects.

The challenge with development is designing a molecule with optimal potency and stability while minimising toxicity”

The challenge with development is designing a molecule with optimal potency and stability while minimising toxicity. With traditional therapies, it may be possible to focus on one aspect of structure or activity, but there is added complexity with an ADC, both in terms of its structure and its modes of action. For example, some design considerations include identifying the type of linker you want to use (cleavable versus non-cleavable), the conjugation chemistry used, the site of conjugation and the drug-to-antibody ratio (DAR). These factors all add variability to your manufacturing process. Controlling any variations is critical, especially during scale up, as any changes made can affect the efficacy and safety of the drug.

As you design your process and its conjugation method, you must not only choose the best development process but also maintain consistency during manufacturing. Key to this is process characterisation. ICH Q8, a guidance document for pharmaceutical development by the International Council for Harmonisation (ICH), states, “The manufacturing process development program or process improvement program should identify any critical process parameters that should be monitored or controlled (eg, granulation end-point) to ensure that the product is of the desired quality.”² The importance of this regulatory requirement is highlighted in other guidelines, such as those published by the US Food and Drug Administration (FDA).³

The more analytical work you undertake in early phases to understand every aspect of an ADC, the fewer surprises you will have at the end and, while analytics may seem like a significant investment up front, it pales in comparison to the expense of a wasted clinical trial or the time it takes to go back and redevelop a molecule. Additionally, being able to demonstrate to regulators that you possess a deep understanding of your molecule and its manufacturing process is necessary when it comes to submission for licensing applications.

The more analytical work you undertake in early phases to understand every aspect of an ADC, the fewer surprises you will have at the end and, while analytics may seem like a significant investment up front, it pales in comparison to the expense of a wasted clinical trial or the time it takes to go back and redevelop a molecule. Additionally, being able to demonstrate to regulators that you possess a deep understanding of your molecule and its manufacturing process is necessary when it comes to submission for licensing applications.

Mitigating risk through product characterisation

There is a wide range of analytical techniques with which to characterise the structure of an ADC. Some analytics may already be involved in your manufacturing process controls, such as high-performance liquid chromatography to characterise the DAR. In addition, more sophisticated approaches provide an in-depth view of the structural and biological properties of a drug. For example, peptide mapping by liquid chromatography–mass spectrometry (LC‑MS) breaks the ADC into fragments in order to determine precisely where the drugs are located on the antibody structure. This can be coupled with hydrogen/deuterium exchange, an advanced technique for measuring the higher order structure of proteins based on isotope labelling of amide hydrogens exposed to the surrounding solvent. Together, this information allows you to consider how the conjugation affects the three-dimensional shape of the protein, which ultimately affects biological activity.

In addition to structural techniques, bioanalytical methods should be used to determine the ability of the ADC to bind to its target in order to assess the extent of cellular internalisation and to measure cytotoxicity (potency). A variety of immunological assays can also be employed to evaluate the ADC’s capacity to engage the immune system to trigger effector functions.

In addition to structural techniques, bioanalytical methods should be used to determine the ability of the ADC to bind to its target in order to assess the extent of cellular internalisation and to measure cytotoxicity (potency). A variety of immunological assays can also be employed to evaluate the ADC’s capacity to engage the immune system to trigger effector functions.

Next-generation analytics can streamline your development by providing the crucial insight needed to make more educated decisions at critical junctures in your development and ensure your drug performs as intended. Working with a partner who has the capabilities to perform this level of product characterisation provides access to new technologies and techniques at the forefront of today’s analytical methods, rather than making long-term investments before you know how your drug will perform in the market.

Next-generation analytics can streamline your development”

If you choose to work with a partner for the development of your ADC, they should have suitable experience in product characterisation, as well as experience and highly specialised capabilities to produce these complex molecules from cell development to commercialisation. This includes equipment, skills, regulatory knowledge and the ability to coordinate activities across the supply chain. Working with multiple partners is already challenging, but it can be exacerbated with ADCs, due to the need to co-ordinate the development of three separate components (antibody, linker and cytotoxin). It is therefore of great value to streamline your ADC development and mitigate risks through product characterisation.

About the authors

Omar Lamm – Product Characterization Technical Specialist, MilliporeSigma. Omar is responsible for field technical support of product characterisation services. Based in Ann Arbor, Michigan, he has 20 years of experience supporting contract biopharmaceutical product development both in the lab focusing on mass spectrometry and full-scale analytical development programmes and in-field client support.

Omar Lamm – Product Characterization Technical Specialist, MilliporeSigma. Omar is responsible for field technical support of product characterisation services. Based in Ann Arbor, Michigan, he has 20 years of experience supporting contract biopharmaceutical product development both in the lab focusing on mass spectrometry and full-scale analytical development programmes and in-field client support.

Martin De Cecco – Principal Scientist for Product Characterization, Merck. Martin supports clients as a subject matter expert for analytical and bioanalytical testing. He has 10 years’ experience developing methods for the structural characterisation of biopharmaceuticals and working in the CRO industry. He holds a PhD in Biophysical Chemistry from the University of Edinburgh and an MSc in Forensic and Analytical Chemistry from the University of Strathclyde.

Martin De Cecco – Principal Scientist for Product Characterization, Merck. Martin supports clients as a subject matter expert for analytical and bioanalytical testing. He has 10 years’ experience developing methods for the structural characterisation of biopharmaceuticals and working in the CRO industry. He holds a PhD in Biophysical Chemistry from the University of Edinburgh and an MSc in Forensic and Analytical Chemistry from the University of Strathclyde.

References

- iHealthcareAnalyst, Inc. (January 2020). Global Antibody Drug Conjugates Market $7.5 Billion by 2025. https://www. ihealthcareanalyst.com/global-antibodydrug-conjugates-market/

- International Council for Harmonisation. (2009). Guidance for Industry, Q8(R2) Pharmaceutical Development. https:// www.fda.gov/media/71535/download

- FDA. (January 2011). Guidance for Industry, Process Validation: General Principles and Practices.

https://www. fda.gov/media/71021/download

Related topics

Antibodies, Drug Development, Drug Targets, Oncology, Research & Development

Related conditions

Cancer

Related organisations

International Council for Harmonisation (ICH), US Food and Drug Administration (FDA)