Automated plasmid purification workflow developed for mammalian cell expression-quality DNA

Posted: 24 February 2022 | Victoria Rees (Drug Target Review) | No comments yet

Eli Lilly scientists report that they have designed, qualified and enabled a high-throughput plasmid purification and quantification workstation.

To accelerate the existing biotherapeutic discovery workflow, a research team from Eli Lilly and Company designed, qualified and enabled a fully integrated high-throughput plasmid purification and quantification workstation which they have termed Automated Miniprep Plasmid Station (AMPS).

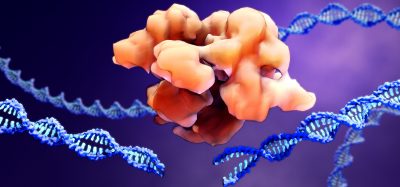

According to the scientists, early-stage antibody discovery and engineering typically require the cloning, expression and screening of large numbers of proteins. Normally, DNA fragments encoding proteins of interest are cloned into extra-chromosomal plasmids that are amplified in Escherichia coli. Following purification from the bacteria, the plasmids are introduced into appropriate cells and the expressed recombinant proteins screened for desired binding or function in a high-throughput manner. Even in a 96-well plate format, plasmid purification from E. coli is typically a labour intensive and time-consuming process.

To speed up this process, the research team developed AMPS, as outlined in their paper published in SLAS Technology. They say that AMPS can purify preparations from 20 96-deep-well plates of E. coli cultures, measure DNA absorbance at 260nm, calculate plasmid concentrations and prepare 96-deep-well plates for mammalian expression in an operator-independent manner. Plasmid yields and concentrations are equivalent to those obtained offline. Furthermore, the quality of the DNA purified on the AMPS is equivalent to that obtained offline in terms of DNA topology and absence of contaminating bacterial chromosomal DNA and RNA. Most importantly, plasmids purified on the AMPS provide similar antibody titers following transfection in CHO cells as plasmids purified offline. The AMPS bridges high-throughput E. coli colony picking capabilities typically available in an automation lab with downstream CHO expression needs and will facilitate screening of large numbers of biotherapeutics in binding and cell assay screens.

Related topics

Antibodies, Assays, Biopharmaceuticals, Biotherapeutics, DNA, Lab Automation

Related organisations

Eli Lilly and Company