Monoclonal antibodies produced by new cell lines hope to improve drugs

Posted: 1 August 2018 | Drug Target Review | No comments yet

Many biopharmaceutical companies look to produce biosimilars soon, since the patents on the original mAb expire over the next few years…

Researchers at the Institute for Bioscience and Biotechnology Research (IBBR) explained how they looked into methods of producing mAb, the world first standardised monoclonal antibody issued by the National Institute of Standards and Technology (NIST), known as NISTmAb.

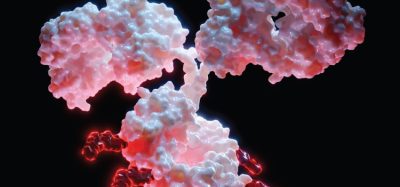

The team engineered three mouse cell lines to produce non-proprietary versions of the monoclonal antibody which resemble the characteristics of the original mAb. Monoclonal antibodies are proteins created by identical immune cells in a laboratory, that can target viruses, disease cells and antigens which trigger immune responses. They can be used to deliver material therapeutically, or radiation to select sites.

Since the approval of the first mAb, their influence on medicine has rapidly increased, with five of the top ten drugs today being mAbs, and annual sales at $100 billion. This is expected to rise to $150 billion within three years.

“By creating the means to produce our already well-characterised monoclonal antibody, the NISTmAb, we can now make the measurements that will define the production process as well as the product,” said NIST research biologist Dr Zvi Kelman who co-authored the mAbs paper. “From that, we can develop a standardised model for monoclonal antibody biomanufacturing that will give researchers and manufacturers a second valuable reference tool.”

Many biopharmaceutical companies will look to produce generic biosimilars soon, especially since the patents on the original mAb expire over the next few years.

“Both the manufacturers seeking legal and public approval for their biosimilars and regulators at the Food and Drug Administration must verify that the new drugs match the originals with regard to efficacy, quality and safety,” said leader of the Biomolecular Structure and Function Group in NIST’s Material Measurement Laboratory, Dr John Marino.

“Having a rigorously characterised mAb production process, along with our standard NISTmAb protein, will serve as powerful benchmarking tools that should help manufacturers and regulators release new mAb therapeutics and biosimilars with greater confidence.”

He added, “Understanding how the NISTmAb is derived will enable investigators to look for ways to optimise the production of other mAbs or overcome commonly shared problems such as contamination or aggregation.”

The study was published in the journal mAbs.

Related topics

Analytical Techniques, Antibodies, Biologics, Disease Research, Drug Development, Drug Discovery, Drug Leads, Research & Development

Related organisations

Institute for Bioscience and Biotechnology Research, National Institute of Standards of Technology (NIST)

Related people

Dr John Marino, Dr Zvi Kelman